PHMSA FAQs Shed Light on Regulations for Midstream Processing Facilities

Midstream processing facilities under Pipeline and Hazardous Materials Safety Administration (PHMSA) jurisdiction should pay close attention to the proposed guidance document issued November 4, 2020.

Per the document summary, “PHMSA is making available for comment a set of draft frequently asked questions (FAQs) regarding federal oversight of midstream processing facilities. Specifically, this guidance will delineate where PHMSA and the Occupational Safety and Health Administration (OSHA) will each perform inspection and enforcement activities for midstream processing facilities where there is overlapping authority.”

Background on the PHMSA FAQs

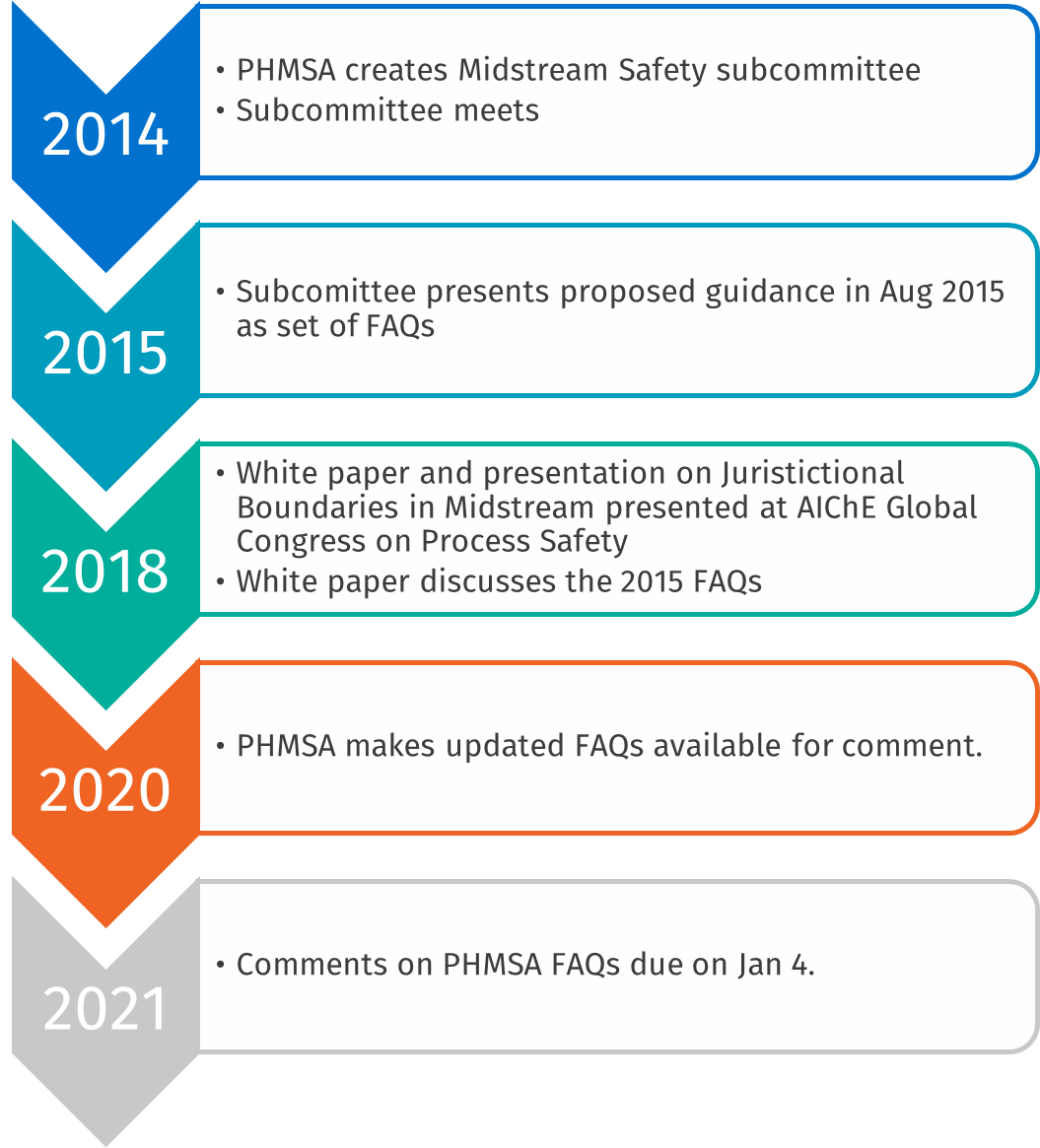

In 2014, the PHMSA Gas and Liquids Technical Advisory Committee presented on the need to create a workgroup of stakeholders to discuss the issues related to regulatory oversight of midstream processing facilities. PHMSA and OSHA are seeking understanding of the concerns of the midstream companies because the agencies are in agreement on jurisdictional lines: OSHA covers gas processing units and PHMSA does not have an interest in regulating processing units.[1]

The subcommittee for Midstream Safety was formed with a goal to provide understanding of the boundaries between PHMSA and OSHA and ensure there are no gaps or overlaps in the regulation.[2]

The PHMSA subcommittee, consisting of representatives of federal agencies and industry, met on several occasions in 2014 and 2015. They presented their proposed guidance in August 2015, which was intended to provide clarity and is not considered to be a legally enforceable regulation. The proposed guidance was presented in the form of a set of frequently asked questions (FAQs).

In April 2018, Provenance Consulting Account Director Lauren Mercer presented the topic of jurisdictional boundaries in midstream at the 2018 AIChE Spring Meeting and Global Congress on Process Safety. The associated white paper contained discussion on the 2015 FAQs.

On November 4, 2020, PHMSA made available for comment the set of FAQs. This article serves as a comparison of the FAQs from 2015 to the 2020 set, contains comments related to the FAQs, and indicates remaining gray areas. Persons interested in submitting comments on the draft FAQs must do so by January 4, 2021…

…Read the rest of the article on trinityconsultants.com.

Recent Posts

View Recent Process Safety Webinars

Learn best practices from our team of knowledgeable experts

We provide on demand process safety webinars covering all PSM topics including PHAs,

mechanical integrity, relief systems and more.

Account Director Lauren Mercer presented her whitepaper “Jurisdictional Boundaries in Midstream: Where is the Line?” at the

Account Director Lauren Mercer presented her whitepaper “Jurisdictional Boundaries in Midstream: Where is the Line?” at the