Midstream processing facilities under Pipeline and Hazardous Materials Safety Administration (PHMSA) jurisdiction should pay close attention to the proposed guidance document issued November 4, 2020.

Per the document summary, “PHMSA is making available for comment a set of draft frequently asked questions (FAQs) regarding federal oversight of midstream processing facilities. Specifically, this guidance will delineate where PHMSA and the Occupational Safety and Health Administration (OSHA) will each perform inspection and enforcement activities for midstream processing facilities where there is overlapping authority.”

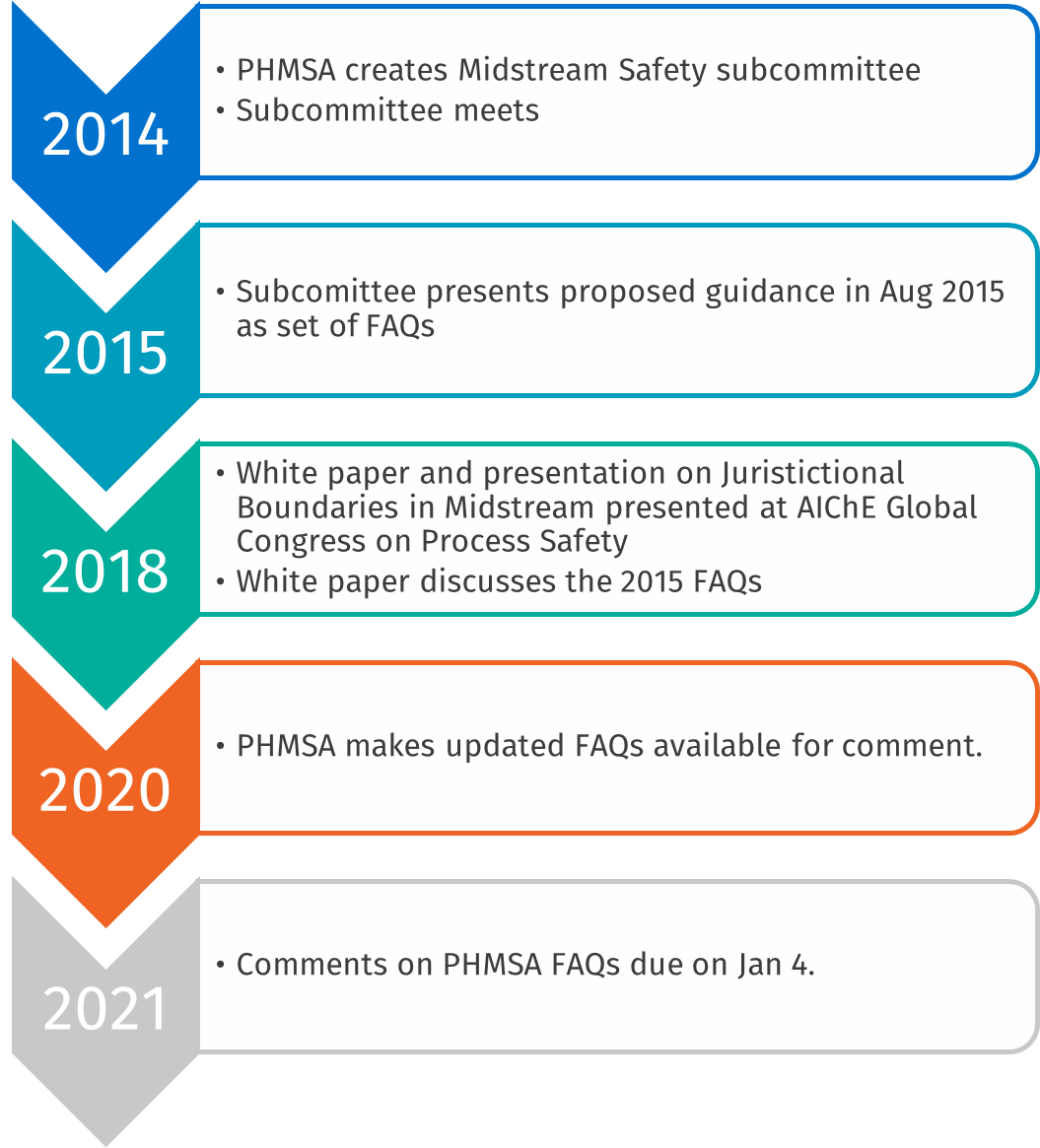

In 2014, the PHMSA Gas and Liquids Technical Advisory Committee presented on the need to create a workgroup of stakeholders to discuss the issues related to regulatory oversight of midstream processing facilities. PHMSA and OSHA are seeking understanding of the concerns of the midstream companies because the agencies are in agreement on jurisdictional lines: OSHA covers gas processing units and PHMSA does not have an interest in regulating processing units.[1]

The subcommittee for Midstream Safety was formed with a goal to provide understanding of the boundaries between PHMSA and OSHA and ensure there are no gaps or overlaps in the regulation.[2]

The PHMSA subcommittee, consisting of representatives of federal agencies and industry, met on several occasions in 2014 and 2015. They presented their proposed guidance in August 2015, which was intended to provide clarity and is not considered to be a legally enforceable regulation. The proposed guidance was presented in the form of a set of frequently asked questions (FAQs).

In April 2018, Provenance Consulting Account Director Lauren Mercer presented the topic of jurisdictional boundaries in midstream at the 2018 AIChE Spring Meeting and Global Congress on Process Safety. The associated white paper contained discussion on the 2015 FAQs.

On November 4, 2020, PHMSA made available for comment the set of FAQs. This article serves as a comparison of the FAQs from 2015 to the 2020 set, contains comments related to the FAQs, and indicates remaining gray areas. Persons interested in submitting comments on the draft FAQs must do so by January 4, 2021…

…Read the rest of the article on trinityconsultants.com.

We provide on demand process safety webinars covering all PSM topics including PHAs,

mechanical integrity, relief systems and more.

For a short two days in October, representatives from various industries and government agencies descended on D.C. for an intensive summit on process safety organized primarily by the law firm Conn Maciel Carey LLP. Other sponsors included API, AFPM, and Sidley Law Firm (EPA regulatory specialists).

The 2nd Annual Process Safety Summit in Washington, D.C., boasted a heavy-hitter list of speakers and panelists from both industry and government sectors.

Provenance Consulting Account Director Dylan Misslin, along with a small team of Trinity Consultants’ PSM specialists, attended the event and enjoyed a significantly positive experience. While developed much more recently than other industry events like the AFPM National Safety Conference or the AIChE Global Congress on Process Safety, the Process Safety Summit (aka “the Summit”) taps into truly actionable information for its attendees.

Eric J. Conn and the Conn Maciel Carey Workplace Safety Practice specialize in OSHA defense, not just process safety management. Their knowledge of how the regulations directly affect their clients plus their contacts within the regulatory world enable them to provide a unique experience.

In addition to this now-annual conference, their blog, “The OSHA Defense Report” provides a treasure trove of resources for anyone wanting to gain a better understanding of the legal side of PSM regulations, citations, and letters of interpretation.

This expertise combined with a smaller attendance (fewer than 250 people) allowed for some engaging sessions with the speakers and panelists (the speaker list is available online). A few notable sessions/topics included:

Conn described the motivation for organizing the event: “The Summit fills an important gap for those impacted by process safety. Though there are opportunities for employers and operators to interact with key government regulators, none of those opportunities focus exclusively on process safety.” He explains, “All other true process safety industry events are far from Washington, DC, making it hard to attract significant representation by senior agency officials and trade group staff.”

In describing the intent of the Summit, Conn noted, “The Summit uniquely focuses on the process safety regulatory landscape and industry best practices. The event covers rulemaking, enforcement programs and matters, significant cases, trends as we move through the Trump Administration, best practices, and other key process safety regulatory issues impacting Industry.”

Overall, Dylan Misslin noted that the Summit seemed more focused on maintaining regulatory compliance by truly understanding the purpose behind the regulation and how it is enforced than just on the mechanics of a process safety management program.

“While everyone can agree that process safety is important because safety is important, the element of compliance cannot be left out of the equation for our clients.”

Mike Kish, Senior Safety Specialist at The Redstone Group, A Trinity Consultants Company, noted that the session on RAGAGEP compliance was particularly interesting.

“I found myself thinking about how RAGAGEP deficiencies landed at the top of the ChemRef NEP citations. While maintaining RAGAGEP compliance is very detailed and labor intensive, it can have serious consequences for our clients if conducted or applied improperly,” he observed.

“The key point I took away,” added Greg Haunschild, P.E., Managing Consultant at Trinity Consultants, “was the importance of defining and declaring the RAGAGEP program for your specific site and sticking with the defined program in all aspects.”

Given that PSM is a performance-based regulation, it is crucial that what you actually do match what you declare.

OSHA assumes that each site chooses their RAGAGEP standard based on the risk within the given process. Haunschild explained, “while a site may choose to set standards beyond minimum requirements, they cannot retract their original declaration in favor of a less-stringent standard if the RAGAGEP isn’t met. Once you declare the bar, you must reach it.”

Curt Petrosky, P.E, CSP, Managing Consultant at Trinity Consultants, has continued to think about the 2019 Wynnewood decision and how it could impact clients.

Given the OSHRC decision’s definition interpretation of “process”, Petrosky notes, “sites should review the boundaries of their covered processes,” to ensure they understand how the decision may impact their PSM applicability across their facilities.

Misslin noted that the benefits from attending this event were far-reaching. “Although D.C. is not the most convenient conference location, having the opportunity to connect in person with major players in the regulatory landscape was a major selling point for me,” he remarked.

The smaller scale of the event and more intimate access to a number of government representatives who are notorious for avoiding industry gatherings en masse made it worth the trip.

Petrosky agreed. “You get to hear regulators from both OSHA and EPA answer pertinent questions and give you a sense of the direction where regulation is headed,” he adds.

One word of advice for future attendees is to choose your table wisely. “Scheduled breaks were short, so most of the networking time happened briefly between sessions among your table-mates. Take the opportunity to get to know those around you whenever you get the chance – the room is full of major players either in the industry or on the regulatory side,” Misslin advised.

Looking forward to the 2020 Summit, Conn noted several major developments that will impact the process safety industries since this past October. From the EPA’s release of the RMP Reconsideration Rule to the CSB’s introduction of a proposed and final Accidental Release Reporting Rule and especially the full briefing about process boundaries in the Wynnewood case before the 10th Circuit Court of Appeals, the 3rd Annual Process Safety Summit in Washington, DC, promises to be another can’t miss event.

Conn shared with us the dates for the event – October 14-15, 2020. So, save the date, and we hope to see you there.

Visit with the Provenance Consulting team at these industry events

We provide on demand process safety webinars covering all PSM topics including PHAs,

mechanical integrity, relief systems and more.

The Provenance team is not only dedicated to providing exceptional client services, we also strive to share our expertise. This past year, our team has participated in educational programming, industry conferences and presentations, and achieved some impressive professional milestones. Check out a brief list of what Provenance team members have participated in.

In my experience, many industry professionals avoid asking “dumb” technical questions openly for reasons of fear or pride. What engineers need are answers to the technical pressure relief systems questions they just can’t find a way to ask. This presentation shared questions submitted from dozens of anonymous engineers when asked, “What do you want to know about pressure relief systems but were too afraid to ask?” It then answers them using the latest RAGAGEP and industry direction.

This presentation discussed the gray area between PSM and DOT jurisdiction, including coverage of Terminal operations (e.g. drying), break-out tanks, railcars/trucks, and cavern applicability. The nuances of PSM applicability, including interconnectivity and colocation, hydrocarbon used as a fuel, atmospheric tanks, and safety systems will be presented. Furthermore, this paper will provide a history of jurisdictional boundary and PSM applicability cases/interpretations and will present examples of determining PSM jurisdiction and applicability.

“It is likely that your problem is with the process and not so much maintenance wash procedures. I recommend looking into the stream components, particularly chloride concentrations. You may have a very-well-known damage mechanism, called ammonium chloride corrosion, at work in your main fractionator tower…” [read more]

“When it comes to distillation towers, you always want to be certain that you put the right pressure relief device (PRD) in the right spot. Due to the complexities of distillation towers, many relief cases can exceed the normal relief rates you see from your typical vessel overpressure scenarios. In events such as these, it’s always good to get an experienced evaluator or a second opinion of the evaluation of your column PRDs…” [read more]

To become licensed, engineers must complete a four-year college degree, work under a Professional Engineer for at least four years, pass two intensive competency exams and earn a license from their state’s licensure board. Then, to retain their licenses, PEs must continually maintain and improve their skills throughout their careers.

In addition, in 2019 Edward Guillen completed his API 653 Inspector certification, making him a rare triple-certified inspector (API 510, 570, 653).

We provide on demand process safety webinars covering all PSM topics including PHAs,

mechanical integrity, relief systems and more.

This past fall, three team members from Provenance Consulting attended and participated in the API Subcommittee on Pressure Relieving Systems (SCPRS) at the 2019 Fall Refining and Equipment Standards Meeting in Atlanta, Georgia. Between enjoying lunch at The Varsity and other popular Atlanta eateries, Justin Phillips, Jillian Hays and James Topp jumped into the thick of the subcommittee meetings.

Justin Phillips, our Relief Systems Line of Service Manager and voting member in the SCPRS, has actively participated in these meetings since 2012.

“As a professional engineer, engaging in these groups is an important way to stay abreast of advances in pressure relief system technology and to influence the application of pressure relief system standards. It’s also a great place to network and maintain regular contact with industry partners and clients.”

Project Lead James Topp volunteered as meeting secretary during the 2019 API meetings for API 520, 521, 2000, and the Joint Session. According to Justin, “This was James’ first time attending the API meetings and he worked hard to keep up with the discussions. His time and contributions are very much appreciated by the chairpersons and task force leaders.”

From his perspective, Topp recognizes the long-lasting benefit of such subcommittee efforts. “It is very useful to see how the industry approaches the issues that come up. Beyond that, it helps develop my own abilities as a consultant and enabled me to meet leaders in the relief systems field.”

The goals of these meetings are to work out disagreements and find broad consensus on the most appropriate way to apply pressure relief systems, while simultaneously networking and sharing Provenance Consulting’s solutions. Our participation as a company demonstrates to clients, partners, and competitors that Provenance Consulting and Trinity Consultants have a bona fide and highly specialized interest in pressure relief systems.

Our representatives are also able to bring meeting news back into the organization for dissemination immediately – with a genuine understanding of the underlying purpose and motivations of the committee.

There are several important milestones approaching for the SCPRS: “We are nearing publication of the next editions of the standards (e.g., API 521), which means that the subcommittee can focus on newer or evolving areas of focus as soon as Spring 2020.

Prediction and avoidance of PSV instability has been (and will continue to be) an area of change as our understanding of the contributing phenomena evolves.

The most heated discussions in the past decade have revolved around the inadequacy of “the 3% rule” to predict PSV instability and the engineering studies that professionals might use to better predict PSV stability (or lack thereof).

For this reason, the next publication cycle of API 520 Part II might see some more interesting changes to address this topic. Set a timer and check back in five years!” suggests Phillips.

Topp adds, “Outside of the focus on valve stability, a lot of the other discussion focused on potential changes related to how the meetings might function and would API try to work with ISO again.”

Experienced project lead Jillian Hays notes that an interesting suggestion was proposed by the new joint committee chairpersons. SCPRS chairs Matt Brewer, BP, and vice-chair Eli Vatland Johansen, Equinor, proposed that a “round table” session could occur in future committee meetings.

“They believe a round table setting would be a more active collaborative use of time on current issues, and it would hopefully pull more involvement than the key dozen or two that speak up during all the other meetings,” Hays explains.

According to Hays, the industry veterans usually speak up every meeting. While it’s important to share industry knowledge, providing an opportunity for some “younger” voices to be heard could create a more inclusive process that allows for smoother generational turnover in future.

The 2020 Spring Refining and Equipment Standards Meeting will take place in April in New Orleans, Louisiana. Our team is looking forward to another successful meeting with leaders in pressure relieving systems.

We provide full pressure relief system support including engineering design, analysis and revalidation, flare and disposal evaluation, process simulations and more.